https://www.lifegate.it/acquisto-consapevole-denim

- |

- There are three fundamental questions to ask yourself before buying a pair of jeans:how and where it was produced and how much it costs.This already gives us indications on its eco-compatibility and ethical sustainability.

- There are more environmentally friendly alternatives, such as jeans made with 100 percent biobased and biodegradable denim or created through upcycling processes.

- Denim is a product that requires a lot of water to make, but it is domestic washing that increases the environmental impact of a pair of jeans:Let's discover some tricks to wash them as little as possible.

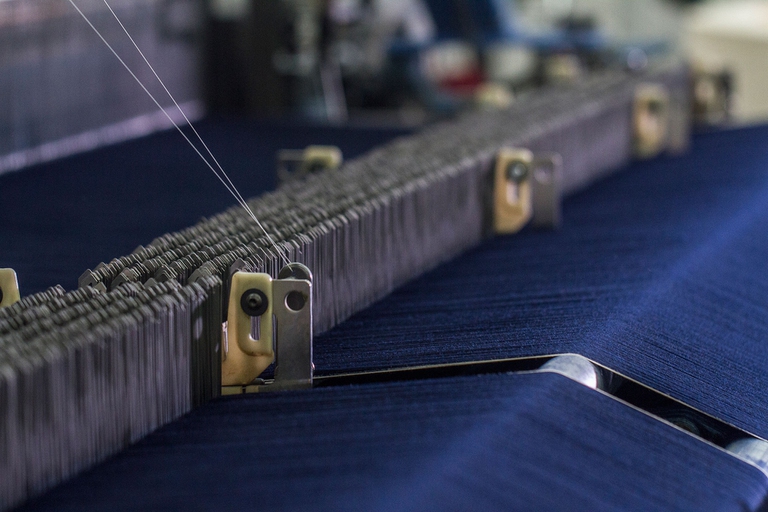

The denim, or the material jeans are made of, is among the least sustainable fabrics that there are:requires many resources in terms of water, energy and chemicals.There are niches of conscious production, but recognizing them is not always easy:Here are some practical tips for making purchases that are as ethical as possible and for extending the life of our new trousers.

Where are jeans produced?

The major problems relating to sustainability derive from the place where a garment is produced, from the materials and technologies that are used.Therefore, there are three fundamental questions to ask yourself before purchasing:how and where the garment is produced and how much it costs.The as is important because the quality of a jeans is directly proportional to its impact on the environment, while the Where it makes us understand if this happens in a country where there are regulations that regulate social responsibility and the treatment of workers.The International Trade Union Organization releases the Global rights index, i.e. a report that assigns a rating to the territories based on the quality of the work.

76 percent of the world's denim is currently produced in five countries: Türkiye, China, India, Bangladesh And Pakistan which, in 2020, all received the worst possible rating.This means that workers are not guaranteed compliance with human rights basic.THE'Italy – one of the nations where the remaining 24 percent is produced – has the best result.Reading on the label of a jeans that it is made in Italy, therefore, already makes the difference.

There are three fundamental processes behind the production of a pair of jeans:work the fabric (i.e. denim), cut it and package it, and then treat it to determine its aesthetics through laundry processes.In the manufacturing phase there is a lower environmental impact in terms of water and chemical agents, but it is greater in terms of emissions.It is then a passage in which, what is crucial, is the labor cost:the quantity of fabric needed to make a pair of jeans has an average price of five euros;to these must be added washing, finishing and packaging.It goes without saying that if the final cost in the shop is twenty euros it means that the workers were paid very little.

How is denim made?

Denim is basically cotton fiber treated with indigo so that it takes on its classic blue color and then subsequently aesthetically defined by color subtraction, through laundry processes.A first step is therefore to recognize the quality of the fiber used, which we can do through the certifications that should be reported on the label, and understand if it is organic cotton. Gots (Global organic textile standard) or if instead there are recycled cotton components Grs (Global recycle standard), both valid.

As for the coloring, the matter becomes more complicated because the indigo that exists in nature (it is an extract of the indigo plant) is a molecule too large to penetrate the cotton fibre.Dyeing made with natural indigo is less stable and requires the use of ten times more chemical agents than synthetic indigo in order to cling to cotton.THE'synthetic indigo it can be in powder or liquid:both are petroleum derivatives, but the second has a greater ability to penetrate the cotton fiber.The washing phase is the most critical:in the five countries mentioned above, old washing machines are still used, which make reckless use of water, chemicals, energy and emissions and, last but not least, do not guarantee the safety of workers.

How far does the product have to travel in total to reach me?

The first thing to do in view of the purchase is get informed, perhaps via the brand's website, to understand what its approach to production is and prefer one short supply chain:the less a product travels, the lower its price will be carbon footprint.

100 percent biobased and biodegradable denim

The global jeans industry is worth it 70 billion dollars:something like 1.25 billion trousers are produced per year.This data makes it clear that the impact of the garment at the end of its life is a crucial issue for evaluating the sustainability of the garment we choose to purchase.In Italy, in Ticino National Park, is home to a denim manufacturing company that, in 2019, launched the first denim in the world 100 percent biobased:that is, made with natural elements and 100 percent biodegradable and compostable.The company is called Candiani and, in the sector, it is synonymous with green and high-quality manufacturing.“The company's virtuous path was somehow 'forced':in 1974 the territory in which it stood was declared a nature reserve;at that point it was necessary to completely rethink and redesign the production line so as not to have to move", explains Candiani's marketing manager, Simon Giuliani.

“This has led the company to be a leader in terms of sustainability:from the cotton fibers that are selected, to the chemicals used, up to the technologies developed in house to dye in the most eco-friendly way possible.However, even in the most environmentally friendly products, a sore point still remained.You can have organic cotton or recycled, dyed with liquid indigo in a dyeing line specifically designed to save water and with a washing method designed to make the process more efficient with less water, fewer chemicals and less energy, but when the garment is disposed of, the part of cotton will biodegrade, but not the stretch part, which is given by the elastic thread:that can take up to two hundred years to decompose.”

Thus he was born Coreva, the completely biodegradable natural elastomer created by the company in five years of research:the solution found to continue producing stretch denim and do it in a green way.However, for the finished product to be thrown into the organic waste, the seams must also be biobased and compostable:there Mic – Italian sewing manufacturing has created a mixed tencel and cotton yarn with these characteristics.All you need to do for jeans with these components is remove the buttons (which can be reused for something else) and then you can happily throw them away.

Upcycled jeans

In Normandy there is the largest warehouse of discarded jeans:they come from all over Europe and the United States and are an incredible resource for those who deal with upcycling. Blue of a kind is an Italian brand specialized in circular design that produces new garments only from existing fabric remnants:or leftovers or discarded trousers.“The first step for us is to select already beautiful fabrics, not too worn so as not to have to intervene with washing or other processes,” he says Fabrizio Consoli, founder of Blue of a kind.

“We only intervene to give a sartorial cut by placing a pre-built waistband inside, which is the typical element of men's tailored trousers.These elements are also all pre-existing materials:leftover cotton or stock belts that have not been used.Therefore, no water is used to make one of our garments.To understand its real impact we need to go back to the origin:the longer the road it took to arrive in Italy, the greater its carbon footprint, but still not comparable to that of a product made from scratch".

Certifications

“To date there is still no impartial institutional body that issues universal declarations on the parameters with which denim is made, but there are separate certifications,” adds Giuliani.“Got and Grs give an indication of the type of fibre, while the ISO 14001 it is the environmental certification which, however, offers an evaluation based on the rules in force in the country in which it operates (obtaining it in Italy is different from obtaining it in Pakistan).The most complete one at the moment is Cradle to cradle (from cradle to cradle):is issued by a non-profit organization and takes into consideration the entire production process:from manufacturing to weaving, up to washing".

Maintenance

“To grow the cotton needed to make a pair of jeans you need an average 2,565 liters of water and, subsequently, 20 liters for the production of each meter and a half of fabric, and then from 70 to 150 in the laundry phase (Candiani only uses ten).But even taking all this into account, 80 percent of the environmental impact of a pair of jeans during its life cycle is caused by domestic washing.Reducing the number of times we wash our jeans is useful for the environment, but also for the look of the trousers themselves, made of a fabric which, due to its workmanship, leads to the formation of natural shades with wear and which when you wash it often they disappear”.

THE'alternative to the washing machine there is, concludes Simon Giuliani:“Putting your jeans in the freezer every now and then is an excellent alternative to washing, because it breaks down bacteria, but you can also turn them over inside out and place in a basin with a little water, a little vinegar and a few drops of fabric softener.Once the trousers have been soaked for a bit, they should then be brushed on the inside to remove the dead skin.In general it is useful to pay attention to the maintenance of the garment, to start with repairs before it is totally ruined".It is an attitude that is standard practice in the world of luxury:we should start adopting it even for more casual garments.