https://www.lifegate.it/terre-rare-smartphone

- |

Plastic, aluminum, carbon fiber, titanium, lithium, neodymium but also gold, tin and tantalum.Inside each electronic device we use there is a small mine of rare and precious resources, the rare earths, which often end up in dump or even we keep them for years and years in our drawers, without thinking too much about them. È a theme that has been known for years, which is often brought up when discussing the environmental impact of lithium batteries, for example, a now extremely precious mineral whose extraction has become a billion-dollar business exposed to many abuses.But the best example to understand how important these often forgotten resources are, and to be recycled, is smartphones.

According to some estimates, in fact, between 2009 and 2023, more than 17 billion smartphones would have been sold:of any type, obviously, but all containing quantities of several hundred elements, minerals and the so-called rare earths.

What are the rare earths in our smartphones?

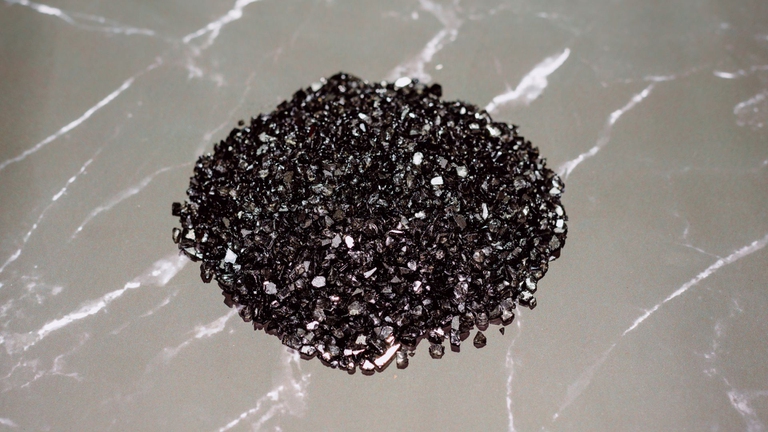

The expression "rare earths" indicates a group of 17 chemical elements of the periodic table, which includes elements such as terbium, dysprosium, praseodymium, neodymium.Despite their name, they are not always "rare" resources, given that they are found in abundance in the earth's crust, but they are often difficult to extract and isolate from other elements.In recent decades, in particular, they have proven to be fundamental in the production of semiconductors, catalysts, optical fibers, solar panels, wind turbines, screens and displays:in short, most of the technologies most important of the twenty-first century.

The success and diffusion of these devices has caused a rush to extract rare earths of historic importance.However, the extraction activities of these elements are expensive, polluting and often carried out in the global South, where the living and working conditions of miners they are very difficult and poorly protected.The exploitation of rare earths generates all kinds of problems, such as thorium contamination, a radioactive element that is released during extraction and can cause serious damage to the environment and people.

Rare earths between environment and geopolitics

All these problems are made even more delicate by a political question, or rather, a geopolitical one, given that China controls 63 percent of rare earth extraction, 85 percent of their work processes and 92 percent of the production of rare earth magnets, which in turn are fundamental for producing radars, missiles, weapons and warplanes.Precisely the export of this type of magnets was affected by a trade block imposed by the Beijing government, announced in December 2023, which was added to similar bans that affected the extraction of the rare earths necessary to produce them.To give an idea of the political tension around these components, in 2022 the Pentagon, alias The US Department of Defense had suspended the delivery of F-15 fighter jets after discovering that an alloy used in magnets came from China.

Recycling and reuse, the treasure inside our electronic devices

Between environmental issues, risks related to radioactivity and trade blockades between superpowers, it's easy to understand why it has become increasingly important to recycle and reuse similar resources.Also because, unlike the fossil fuels, which are "burned" and lost forever once consumed, these minerals can be recovered and reused.Indeed, succeeding in this recycling undertaking is considered one of the essential steps to eliminate, or eliminate, carbon emissions, even in the face of a notable increase in the consumption of rare earths (280 thousand tonnes were extracted in 2021;according to experts, by 2040 the quantity will be seven times as much).

Daisy and Apple's robots to "disassemble" iPhones (and recycle them)

In this regard, Apple - the American multinational that designs and manufactures smartphones, but also computers and other devices - has recently presented Daisy and Dave, two industrial robots capable of quickly disassembling many disused iPhone models, extracting the most important and recyclable parts, such as batteries, photographic lenses (the front and back ones) and motherboards.This allowed, from 2022, to produce iPhone models containing 99 percent recycled tungsten, equip with completely recycled aluminum structures several products (including the latest iPad, MacBook Air and Apple Watch SE) and use only recycled gold for all iPhones, from 13 onwards.Daisy deals with devices that have reached the end of their life and come from trade-in programs with which the company withdraws products that are no longer in use (or that users want to recycle).

The company is aware of how many similar devices rest on the shelves of millions of people, forgotten but still valuable:“It's important that those products stay in circulation,” he explained Sarah Chandler, vice president of environment and supply chain innovation at Apple, to ensure recycling.The company is aware of having to coordinate a huge production chain spread throughout the world, but Apple seems to focus heavily on these objectives:“We have been very clear about our intentions and our goals,” Chandler said, recalling that Apple set a goal in 2020 to become carbon neutral by 2030.“And this also includes our supply chain,” which is helped in this process.Making these processes more efficient, less energy-intensive and more sustainable "is good for the environment and also good for the companies themselves".It is a complex process "but it becomes fast if we do it together", he concluded.

Daisy is a robot large with several arms and tools with which to open, detach and dissect iPhones, isolating individual precious elements which are then processed.From one ton of iPhone motherboards, which are the main electronic boards of a device, Apple is “capable of recovering the same quantities of gold and copper as it would from two thousand tons of mined rock,” according to the annual report on the company's environment. The technology behind Daisy is open and available to researchers and other manufacturers to speed up and improve their disassembly process.

The rare earths forgotten in our drawers

These new tools for recycling they must also inspire a change in consumer habits:each of us probably has a nice pile of rare earths and other "precious" elements, kept in drawers and forgotten for years.They come from phones, tablets, hard drives and other devices that we no longer use and that they cannot be thrown in the garbage.Second a study published by the journal Nature Geoscience, reusing or recycling rare metals from these devices could satisfy up to 40 percent of rare earth demand in China, Europe and the United States by 2050.