https://www.lifegate.it/innovazioni-sostenibili-moda

- |

There sustainability in fashion it is an asset that is more essential than ever for companies, but it is not so easy to achieve, especially when it comes to reverse the direction of production processes already consolidated.In this sense, not only having a long-term strategy, but also having the ability to invest in plays a fundamental role innovation, perhaps equipping itself with its own internal organ capable of carrying out this specific function.What actually happens is that not all the innovations available on the market today are easily adapted to one's business model or type of product.The major experiments, nowadays, mainly concern materials And production processes.On the one hand there are suppliers and producers and on the other there are fashion brands that want to find sustainable innovations, but at the same time must continue to guarantee the same quality and the same creativity ever.The process is very different depending on whether we are dealing with large groups or small brands, which are often single professionals and cannot count on either a real structure or large capital injections.

Small fashion brands are teaming up to find sustainable innovations

Working, both on materials and on processes, is enormous resource-intensive and requires an ad hoc team.The solution, often, is to join forces.“More and more groups and communities of professionals are emerging who come together and which serve to encourage the exchange of experiences” he explains Elena Ferrero, CEO and co-founder of Reform Atelier, company that offers a consultancy service for the textile supply chain regarding circularity and post-consumer recycling. “Rén Collective for example it is a brand collective, artisanal and otherwise, which uses a very simple tool like a Telegram group to exchange useful information.This is a good place to look for suppliers, for example of deadstock fabrics or perhaps a specific type of material, such as regenerated yarns:it's one knowledge exchange and information that helps the smaller businesses in particular."Small manufacturers often do not have large capital to invest in research and development.Furthermore, the use of innovative machinery and materials often involves the need for order large quantities which, therefore, become an important barrier to access for those entities that are not able to support onerous orders.

“We, as Atelier-Riforma, are among the founders of Responsible fashion movement which was born last year and which, among its various purposes, also has that of encouraging discussion and innovation for Italian brands and companies operating in the textile sector.To do this we schedule periodically talks and discussions on innovative materials, processes, digital product passports and similar, analyzing case studies and exchanging points of view.This serves to facilitate the innovation process by companies, but not only.Among the future activities of the MMR there is also that of facilitating the raising of funds for the green transition by small and large brands through joint participation in national or European tenders, as well as the creation of a portal that acts as a tool for exchange and training for businesses (where they can ask questions and receive answers and advice from experts).Often then, there are also gods linked to winning the tender coaching paths, especially useful for smaller businesses.Another very effective reality, for example, is Enterprise Europe Network, which helps companies access tenders for internalisation, establish collaborations with companies located abroad or participate in international fairs and events.Luxury brands and large holding companies generally have no interest in teaming up because they have all the means to do so and, generally, they do not share the results they have achieved in order to maintain their exclusivity".

Circularity:What is the starting point?

“We deal above all with innovation in the manufacturing sector circularity so, first of all, let's analyze the compliance of the brand on the relevant legislation on the matter" continues Elena Ferrero.“The next step is to see how theeco-design, so what are the principles adopted to make the product more recoverable and recyclable at its end of life and what could be the ways of recovering and valorising waste, in a 360 degree approach.Then everything is up to the customer:it is the company that decides what it wants to invest in and often, and I say this with a bitter taste in my mouth, it is not an all-round project.Much more likely the tendency is to focus on one product niche, so we're talking about a small project upcycling, or or a "spot" take-payback service (i.e. a post-consumer clothing collection initiative), while the most interesting thing for a brand would be to start a real path towards circularity".

When large fashion holding companies equip themselves with an ad hoc department for innovations

The large holdings and i luxury brand, if on the one hand they are slow precisely because they are very structured and divided into different departments which are difficult to coordinate with each other, on the other they can count not only on huge resources in economic terms, but often also on departments created ad hoc to accelerate the innovation process in terms of sustainability.It may also happen that there are some joint ventures between brands producing raw materials, such as yarns, and brands producing finished products, i.e. clothes.This is the case, for example, of collaboration between Kering, a luxury holding company that controls among others Gucci, Saint Laurent And Balenciaga, And Albini group, a manufacturing company premium yarns.“Kering's Innovation lab is based in Milan to be at the heart of the decision-making process:it has various departments, but in fact it is a collector because the experimentation is done directly on the production lines" he explains Christian Tubito, Kering Material innovation lab director.“It is not possible to bring together in one place all the machinery necessary for productions as diverse as ours, which is why the Lab is the central body, but the experimentation actually takes place in the individual production lines.Or it happens that the experimentation is carried out in collaboration with a supplier, as in the case of Albini Group".

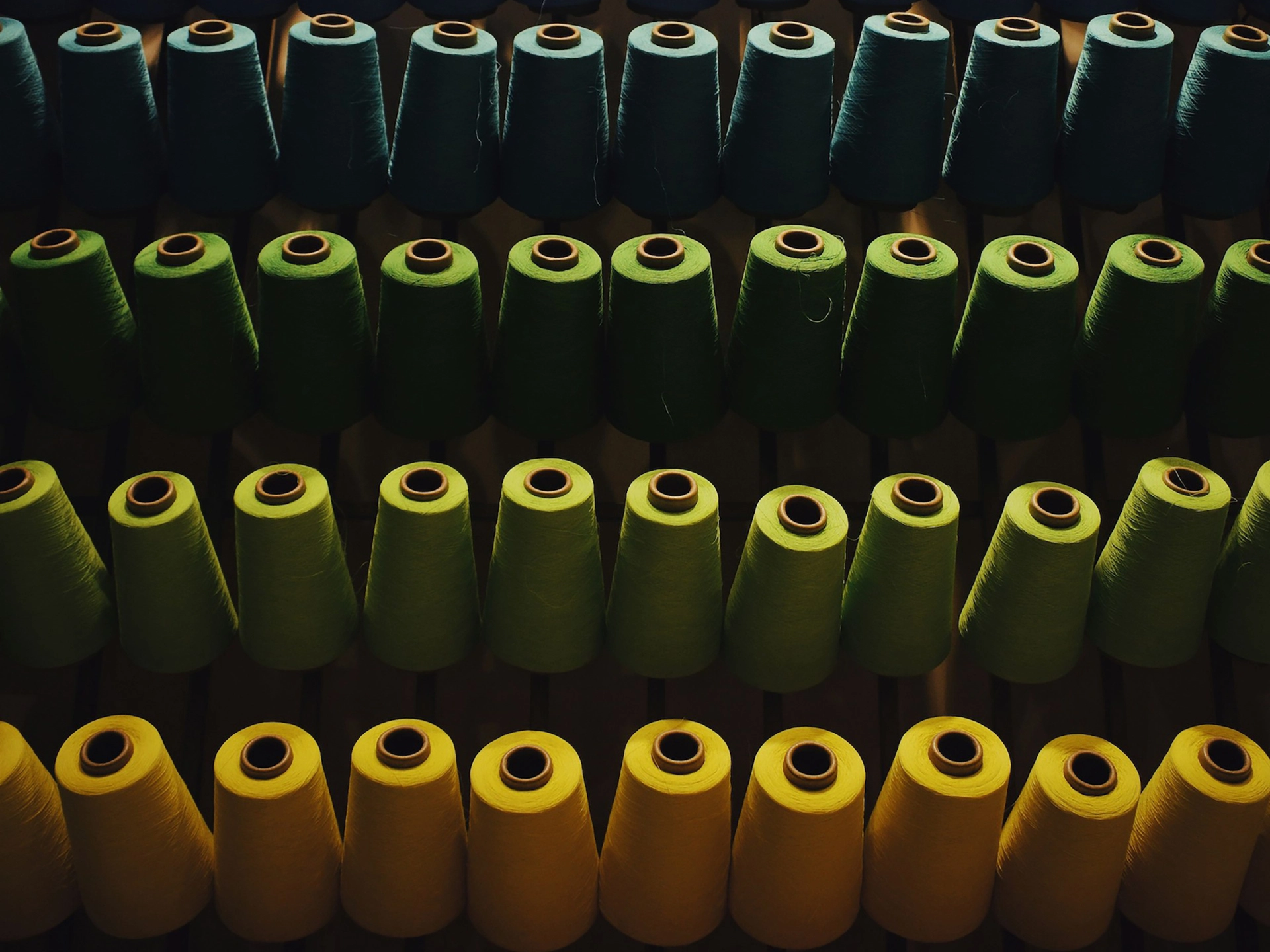

The theme of supply chain it is crucial for large groups and presupposes the alignment of all stakeholders:“Not everyone can accept uncertainty on the part of their suppliers, but it is a necessary requirement for transformation” continues Tubito.“Take for example the farmers of cotton which must convert standard production into regenerative agriculture:this alone presupposes an enormous effort on their part, which is then necessarily followed by all the relevant evidence adapt production with the new material.Sustainability in luxury is not an economic asset, quality is the main aspect in this segment.For us, implementing organic cotton in the collections was enormously difficult, because this type of fiber has impurities that the normal one does not have, so for us it involved enormous work and many tests before being able to replace it completely.It may even happen that a pilot project, perhaps developed for a specific brand, is then internalized by the supplier but not used by the brand, because the result is not in line with its standards or with the aesthetic result it wants to obtain.In the panorama of fibers and gods recycled materials, for example, it is necessary to carry out several tests before finding the combination that perfectly replaces the virgin material".

A compromise between sustainability, creativity and exclusivity

It is crucial for luxury brands to differentiate their materials from those used by their competitors:The luxury lives on exclusivity and a brand in this segment will never accept that the same fiber with the exact same shade of color is used by someone else.This is why collaborations like those between Kering and Albini make sense, a manufacturer that is working in terms of updating processes so that they are less impactful. Albinos is focusing its efforts in particular on those of dyeing, which make extensive use of chemical pollutants.“We have long since started experimenting with the dyeing of textile fibers using microorganisms,” he intervenes Giorgia Dear ones, Innovation Manager & Head of ALBINI_next.“Leveraging the principles of fermentation we feed bacteria capable of producing color:this allows us to dye without producing toxic waste. At the moment, however, not all colors can be done like this.Red, for example, cannot be obtained through bacteria, so we need to find the right balance between the needs of the brands we supply in terms of design and the need to find less impactful solutions."

Find the point of balance between the expectations of creatives and the limits of experimentation is the most difficult thing in innovation processes in the field of sustainability, but it is a process that can also bring new and unexpected implications.“A very interesting thing about dyeing with microorganisms, for example, is that they react differently depending on the materials to which they are applied.A bacterium applied to a certain type of silk produces a bright purple, but does not give the same color when applied to cotton or wool.The areas of exploration are many and varied, it's just a matter of finding the right correspondence between aesthetic rendering and new process".